The world of stainless steel woven wire mesh is both complex and fascinating. Expert Richard Smith, a leading engineer in the mesh industry, once stated, "Choosing the right stainless steel woven wire mesh can significantly impact project efficiency." His insight highlights the importance of selecting the best options available.

In 2026, various choices exist. Each type has its own attributes and applications. For instance, the durability of stainless steel woven wire mesh makes it essential for industries like food processing and construction. Buyers often struggle to navigate this market due to overwhelming options.

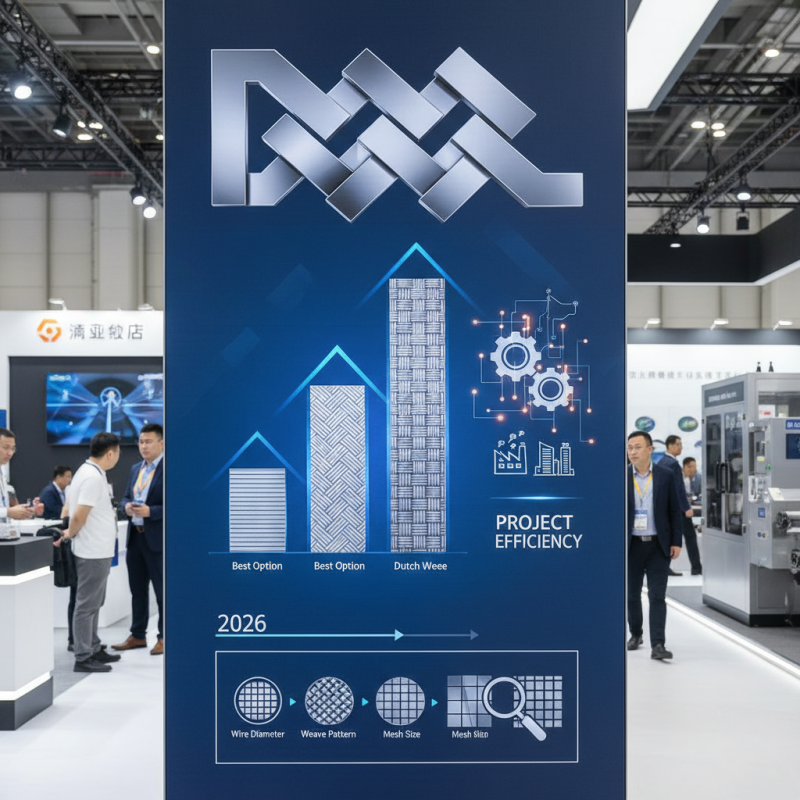

Additionally, pricing can vary widely. Some products may not meet quality standards despite a low price tag. Consumers need to be vigilant in their assessments. Ultimately, understanding factors like wire diameter, weave pattern, and mesh size is crucial. Missteps in selection could jeopardize project success, leading to costly delays or failures.

Stainless steel woven wire mesh is known for its durability and versatility. It is commonly used in industries such as food processing, mining, and construction. According to industry reports, the global stainless steel wire mesh market is expected to grow at a CAGR of 5.3% over the next five years. This growth reflects the increasing demand for materials that can withstand harsh conditions while maintaining structural integrity.

One of the main features of stainless steel woven wire mesh is its corrosion resistance. This makes it suitable for applications exposed to extreme weather or chemicals. The mesh is also highly customizable, with various wire diameters and mesh openings available. These options allow for tailored solutions to meet specific industry needs. However, buyers sometimes overlook the importance of selecting the right specifications. Miscalculating requirements can lead to suboptimal performance.

Another benefit is ease of maintenance. Stainless steel mesh can often be cleaned and reused, reducing costs long-term. Despite its advantages, some users report challenges in sourcing high-quality products. Quality control can vary, leading to inconsistent results. Understanding these factors is crucial to making informed decisions in purchasing stainless steel woven wire mesh.

Stainless steel woven wire mesh comes in several types. Each type serves unique needs. Common configurations include plain weave and twill weave. Plain weave offers a balance between strength and flexibility. It is ideal for filtration and security applications. Twill weave, on the other hand, provides increased flexibility. This makes it suitable for items exposed to high stress.

Different applications require specific mesh characteristics. For example, larger openings may be needed for air or liquid flow. Smaller openings are suitable for finer filtration. There’s a misconception that thicker wires are always better. In some cases, thinner wires work effectively while reducing weight.

The aesthetics of stainless steel mesh can vary as well. Some applications prioritize looks, while others focus on functionality. It's crucial to analyze the environment where the mesh will be used. Corrosion resistance may be necessary in certain industries. Therefore, understanding the right type of woven wire mesh is essential for making informed choices.

Choosing the right stainless steel woven wire mesh requires careful consideration of several key factors. Durability is paramount. Look for a product that withstands harsh conditions. The wire gauge affects strength; thicker wires provide more resistance. However, they might be less flexible. Balance is essential.

Mesh size impacts functionality. Smaller openings offer better filtration while larger openings allow for airflow. Consider your specific needs. For instance, in industrial settings, airflow might be vital for equipment cooling. On the other hand, filtration processes will require finer mesh.

Tip: Always check the material's corrosion resistance. Stainless steel varies in grade. If used outdoors or in humid places, higher-grade options perform better. Additionally, review the mesh's weave pattern. Different patterns may suit various applications. Don’t overlook these details—they can influence the effectiveness significantly. Finding the perfect mesh is a journey, not just a choice. Be patient and diligent.

This chart displays key specifications for the best stainless steel woven wire mesh options available in 2026. It highlights five important factors: mesh count, aperture size, wire diameter, tensile strength, and corrosion resistance.

Maintaining stainless steel woven wire mesh can significantly extend its lifespan. Regular cleaning is crucial to prevent corrosion, especially in harsh environments. Industry reports indicate that over 50% of mesh failures arise from inadequate maintenance practices. Routine inspections выявляют rust, dirt, or debris. Immediate action can prevent small issues from escalating.

Using a mild detergent and warm water is effective. Scrubbing with a soft brush can remove stubborn stains without scratching the surface. Applying a protective coating every few years can enhance durability. Experts recommend following manufacturer guidelines as conditions vary. Ignoring these steps could lead to expensive replacements.

Even with proper maintenance, wear and tear occur. Factors like humidity and exposure to chemicals can accelerate deterioration. It is vital to adjust maintenance practices based on the environment. Regular assessments help identify potential problems before they become critical. Skipping these tasks may compromise the mesh integrity and its performance.

The stainless steel woven wire mesh market is witnessing significant growth. According to recent industry reports, the global market is projected to reach $1.5 billion by 2026. This surge is driven by rising demand across various sectors like construction, filtration, and agriculture.

Several leading brands dominate the market, each offering unique features. Some focus on corrosion resistance, while others prioritize strength and durability. A comparative analysis shows that stainless steel wire mesh is favored for its longevity and low maintenance. Interestingly, not all products live up to their marketing claims. Some brands lack consistency in mesh size, impacting quality.

Customers often face challenges in navigating these options. Reports indicate that nearly 30% of buyers express concerns about product performance. Choosing the right mesh requires careful consideration of its application. Factors like wire thickness and weave pattern play crucial roles. As the market evolves, brands must reflect on their offerings and strive for improvement to meet rising consumer expectations.

Update your browser to view this website correctly. Update my browser now