In the world of industrial fabrication, the wire mesh weaving machine plays a crucial role. According to industry expert John Smith, “Wire mesh weaving machines revolutionize the way we create functional mesh products.” This innovation allows manufacturers to produce intricate wire mesh designs efficiently.

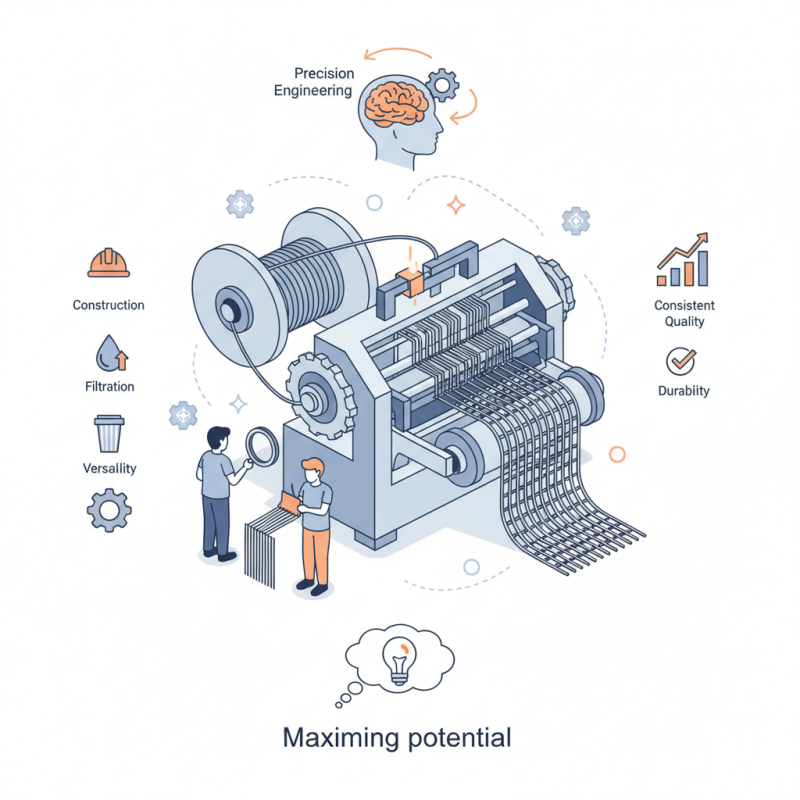

The wire mesh weaving machine combines precision engineering with advanced technology. This combination ensures consistent quality and durability in each weave. Many industries rely on these machines for various applications, from construction to filtration. The versatility of the wire mesh is astounding. Yet, not all machines operate flawlessly, leading to potential quality issues.

Understanding how a wire mesh weaving machine functions is essential for maximizing its potential. It involves feeding wire through weaving mechanisms, creating a mesh pattern. However, human oversight is critical. Operators must frequently check for errors that machines may overlook. Investing in training can help mitigate such problems and improve output quality.

A wire mesh weaving machine is a specialized device used to create various types of wire mesh products. These products are widely used in construction, agriculture, and industrial sectors. The machine interlaces wires in a systematic pattern, forming a strong, durable grid. Reports indicate that the wire mesh market is projected to grow at a CAGR of 5.2% from 2021 to 2026, driven by rising construction activities and infrastructure development.

In operation, a wire mesh weaving machine can process different wire diameters and materials. It employs various techniques like plain weaving, twill weaving, and Dutch weaving. Each method produces a distinct type of mesh, catering to specific applications. For instance, plain weave is commonly used for filters, while Dutch weave is favored for high-strength applications. However, the setup of these machines can be complex, leading to challenges in achieving uniform outputs.

The intricate process requires skilled operators to monitor weaving speeds and ensure quality. There is an ongoing debate about how automation can reduce human error while increasing production rates. Factors such as machine maintenance and operator training significantly influence the overall efficiency. As industries evolve, manufacturers must reflect on these aspects to enhance their operations and adapt to market demands.

A wire mesh weaving machine is a fascinating piece of equipment. It consists of several key components that work together to create intricate wire mesh patterns. The primary element is the weaving mechanism, which interlaces wires systematically. This mechanism can vary, but it generally uses a series of spindles and needles. These parts dictate the mesh's size and design.

Another vital component is the wire feeding system. This system delivers the wire material to the weaving area. It must operate smoothly to ensure uniform tension. If the feeding is uneven, it can lead to flawed mesh. The machine also includes a take-up system. This aspect collects the finished mesh, allowing for continuous production.

Lastly, the control panel offers operators the ability to adjust settings. However, this aspect can be challenging for some. It requires a certain level of technical skill. Users may encounter hiccups in operation, leading to frustration. Each component plays an indispensable role, but they might require frequent adjustments and reflections on performance. Balancing efficiency and quality can be a tricky endeavor.

The weaving process of a wire mesh weaving machine is fascinating. It begins with selecting the right type of wire. This wire is then unwound and straightened. The machine prepares for the weaving process by threading the wire through various components.

Next, the machine starts weaving. The first wire is set vertically while the machine weaves the horizontal wires. It’s essential that these wires are spaced accurately. Any misalignment can lead to weak mesh. The machine continues to weave, creating a pattern that defines the mesh.

Eventually, the woven mesh goes through a quality check. This step is often overlooked but is crucial. Defects can compromise the entire structure. If everything checks out, the mesh is cut to the desired length. However, the process may still have room for improvement, especially in its efficiency.

| Step | Description | Materials Used | Applications |

|---|---|---|---|

| 1 | Setup of the weaving machine with necessary configurations. | Wire (steel, aluminum, etc.) | Construction, Agriculture |

| 2 | Feeding of wire into the machine. | Spools of wire | Fencing, Industrial |

| 3 | Weaving process begins, with the wire being interlaced. | Wire | Screening, Security |

| 4 | Finalize the mesh, cutting it to desired dimensions. | Finished wire mesh | Construction, Manufacturing |

| 5 | Quality control and inspection before packaging. | Wire mesh sheets | General use, Industrial |

Wire mesh products have diverse applications across various industries. In construction, wire mesh reinforces concrete, providing support and strength. It ensures durability for structures, from sidewalks to high-rise buildings. The mesh adapts to different sizes, enhancing flexibility in design.

In the agricultural sector, wire mesh plays a vital role. Farmers use it for fencing, protecting crops from animals. It’s also essential in creating cages for poultry and other livestock. However, choosing the right gauge and size is crucial. An incorrect choice may lead to ineffective protection, resulting in losses.

The automotive industry employs wire mesh for filters and screens. These products improve airflow and prevent debris in engines. However, not all wire meshes are equally efficient. Some might clog easily, leading to potential engine issues. This highlights the importance of selecting high-quality materials for optimal performance.

Proper maintenance of a wire mesh weaving machine is essential for optimal performance. Regular inspection is crucial. Check for any wear and tear in the components. Over time, parts may loosen or become misaligned. This can affect the quality of the mesh produced. Tightening bolts and adjusting the tension are simple repairs you can undertake yourself. However, some issues may require professional help.

Lubrication is another key aspect. Machines should be oiled regularly to ensure smooth operation. A dry machine can lead to overheating. This can result in significant damage. Keep an eye on the lubrication points. If they are dry, apply the correct oil. It can extend the machine's lifespan significantly.

Cleaning the machine is equally important. Dust and debris can accumulate in hard-to-reach areas. This can interfere with the weaving process. Regularly clean the machine using a soft cloth or a brush. Neglecting this can affect performance over time. Also, be mindful of the electric components. Water or excessive cleaning fluid can cause short circuits. Proper care keeps the machine running smoothly and efficiently. Don't overlook the small details. They often lead to bigger problems.

Update your browser to view this website correctly. Update my browser now